Ten things to consider for a successful FTIR installation

FTIR process analyzers have been used in the petrochemical and Refinery Industry for several decades and like other high-end complex systems, quite often need regular maintenance and looking after.

For some of the tougher applications; in particular gasoline and diesel blender stream analysis the failure rate of this technology is higher than you would expect.

This examines why such complex systems can fail and ten steps you can perform to improve the chances of a successful long-term installation.

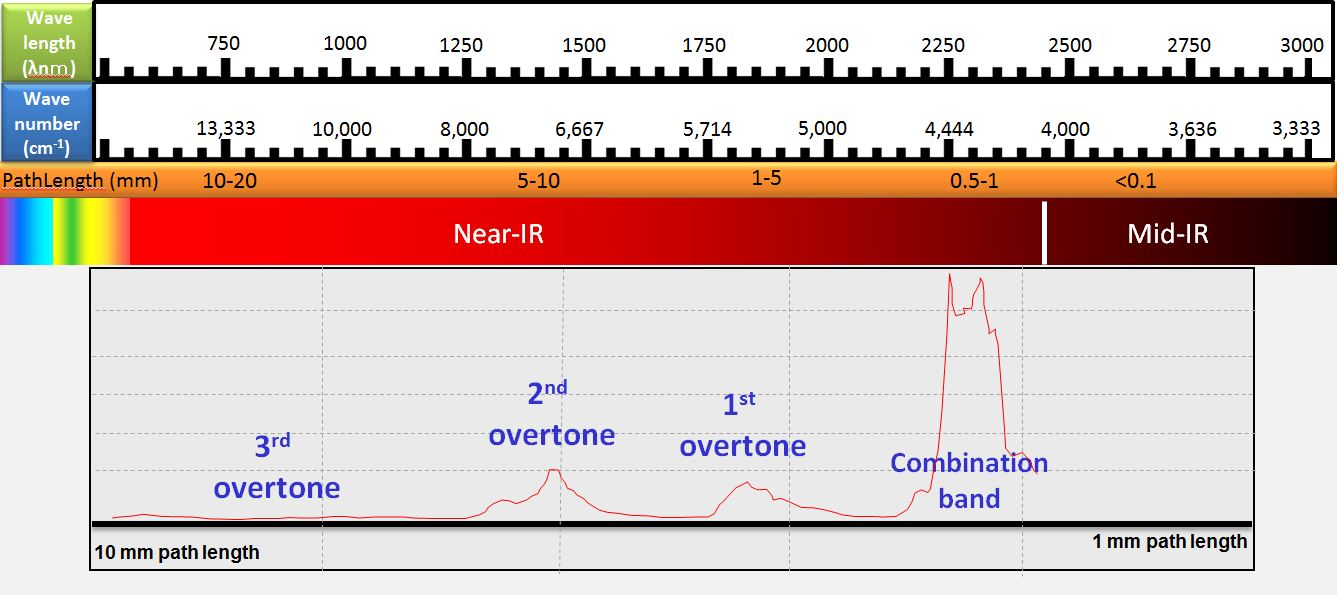

It’s worth mentioning the differences between ‘FTIR’ which refers to Fourier Transform Infrared in the Mid-Infrared part of the spectrum (300-4000cm-1) and ‘FTNIR’ which is ‘’Fourier Transform Near Infrared’’ spectroscopy (4000-13000cm-1).

Figure 1 : Electromagnetic spectrum Infrared

While measurements in the Mid-IR can be far more sensitive then in the Near Infrared (NIR), FTNIR is more commonly used in process applications because it has a number of practical advantages.

Firstly the optical materials used are more robust and suitable for process applications; the insitu probes or transmission cells that are most commonly used need to have optical windows that transmit the light through into the sample and back into the fiber optic. Just like a regular window in your house has to be naturally transparent to sunlight, so does the cell window have to be transparent to Infrared light. Mid-IR transparent materials are quite often brittle and hydrosopic salts like Barium Chloride. For Near Infrared you can use quartz or even sapphire which are pretty tough.

A second reason is that cell pathlengths for Mid-IR are typically 200-500 micron size and more suscepticble to fouling. Near-IR uses pathlengths between 0.5-20mm making it a more practical.

Finally, cheap silica-based fiber optics can be used to great effect – having the spectrometer located hundreds of metres away from the measurement point, and even having multiple streams at different places in the plant feeding to just one spectrometer.

While the Mid-IR can show sharp well defined peaks for various components the Near Infrared shows us the overtone absorbances of hydrocarbons and chemometric modeling needs to be used on the spectra to obtain property values from the samples.

That one word ‘’chemometrics’’ is enough to put some people off, and for good reason. Instead of classifying peaks and counting the area underneath it, chemometrics can be a world of voodoo statistics. Despite the elegant software tools available, it is still too easy to massage the data any way you want and make models that in the field, just don't work.

But it gets worse. The central premise behind using a full range spectrometer to make predictions of properties of certain liquid streams is that the spectrometer can fully measure and differentiate the chemistry within the sample.

In many cases it, the spectroscopic method alone can be woefully inadequate, and the models built for such properties can have arbitary and non-existent correlations.

Online FTIR/FTNIR analyzers are very powerful and can be used to great effect if done correctly.

So here it is, ten things to consider. Many are hardware based reasons but many are modeling based.

Ten things to consider for a successful FTIR installation :

1. Proper extractive sample system.

Extractive sample systems are generally more stable and reliable than insitu probes. Exceptions can be when the sample is too hot or too delicate and has to remain in the process. Otherwise a good sample system regulating the pressure & temperature, flow and particulates is the best way forward.

2. Control the temperature (and pressure)

Infrared is greatly influenced by temperature so controlling within +-2C helps give a stable spectra. The best way is to use chiller water to cool the sample 5-10C and then slowly reheat 5C to give a nice stable temperature. When building correlative models it helps to limit the degrees of freedom - or control the other variables as much as you can. All analyzers use the ideal gas law :- PV=nRT and n (or concentration) is found more easily if 'P' and 'T' and 'V' remain constrained.

3. Remove water

For samples such as gasoil and diesel there can be alot of entrained water which can affect the measurement. By cooling & reheating as mentioned above, plus using a coalescing filter mid-way, much of the water can effectively be removed.

4. Quality of the Fibre Optics

If using fiber optics, make sure they are of a superior quality, and preferably fully encapsulated in kevlar or a protective material. Many low cost Low hydroxide cables available can degrade significantly in less than ten years.

5. Analyzer mounting

Mount the analyzer(s) in an airconditioned and/or heated Enclosure, preferably walk-in shelter, but Field cabinet is also possible.

6. Enclosure Sample Handling System (SHS)

Sample System should be in winterized enclosure. Depends greatly on the location, but an enclosure/weather protection with heating always helps with stability of spectra obtained.

7. Arbitraty correlations in Spectra

Identify which properties have strong, weak or arbitary correlations with the spectra and plan accordingly. Some properties (like RVP or distillation points) have arbitary correlations so may require an additional RVP analyzer if this property is important. During the sales process the tendancy is that everybody involved want too much from the analyzer. It is better to be more realistic and plan accordingly.

8. Grab sample

If feasible install and automatic grab sample collection bottle on sample system. When the analyzer registers an outlier a sample is collected. This semi-automates the process of updating outliers (sample the model does not recognize) and reduces sample handling errors between the site and laboratory.

9. Easy transfer of spectra

Have a laboratory FTIR unit which shares same spectrometer parameters as the online unit as much as possible. This should allow ease of spectral transfer between the two units. Having two spectrometers on site also gives you a heads up if one of them is not working properly.

10. Training or laboratory and site personnel

Properly trained Laboratory and site personnel involved with this analyzer. Site personal should know how to correctly collect samples for lab analysis without compromising sample integrity. Similarly, lab personnel should be fully trained on both analyzers and sample preparation to avoid errors creeping into the calibration models. This training can often be provided by the supplier of the analyser or a specialized company such as ProSCS.

You can also find this blogpost at https://sites.google.com/proscs.co.uk/proscs/blog

January 2018

https://analyzedetectnetwork.com